Note that the feed-in and feed-out devices can be regarded as the special workstations so that they are denoted as Ws 1 and Ws n respectivelyThe superscript Gr denotes the gripper type say single- or dual-gripper while the subscript Lo. UR integration made simple.

It is also called synchronous transfer since all parts are moved simultaneously to the next stop.

. For light work Minimize lifting Follow a rhythm Cellular Flow. Types of controller manipulator end effectortooling eg pneumatic suction cup hydraulic electrical and. Ergonomic Factors in Work Station and Product Design Design the work to.

Process Planning involves planning the processes and workflow in the work cell. To ensure you have the most efficient layout for your facility follow these five stages. Intermittent Transfer 2Continuous Transfer3Non-Synchronous Transfer Intermittent TransferThe parts are moved in a start-and-stop motion from one station to another along the line.

Turnkey cells are fully integrated pre-engineered solutions. How will a work cell benefit you. With the Visual Components Simple Robotics toolkit users can intuitively teach tasks to a robot and validate the design of the robot work cell.

Textbook Solutions Expert Tutors Earn. CHAPTER ELEVEN ROBOT CELL DESIGN AND CONTROL Industrial robots generaliy work with other pieces of equipment. Initial familiarization with the technology Plant survey to identical.

The problem of designing robotic work cells has become a major field of research. Vector indicates the cell with n identical workstations at each stage and m robots. Top 5 robot trends in 2022 according to the IFR.

You should begin by analyzing how human workers are currently performing the task. Robot cells are sometimes referred to as workcells. For light work Minimize lifting Follow a rhythm Cellular Flow.

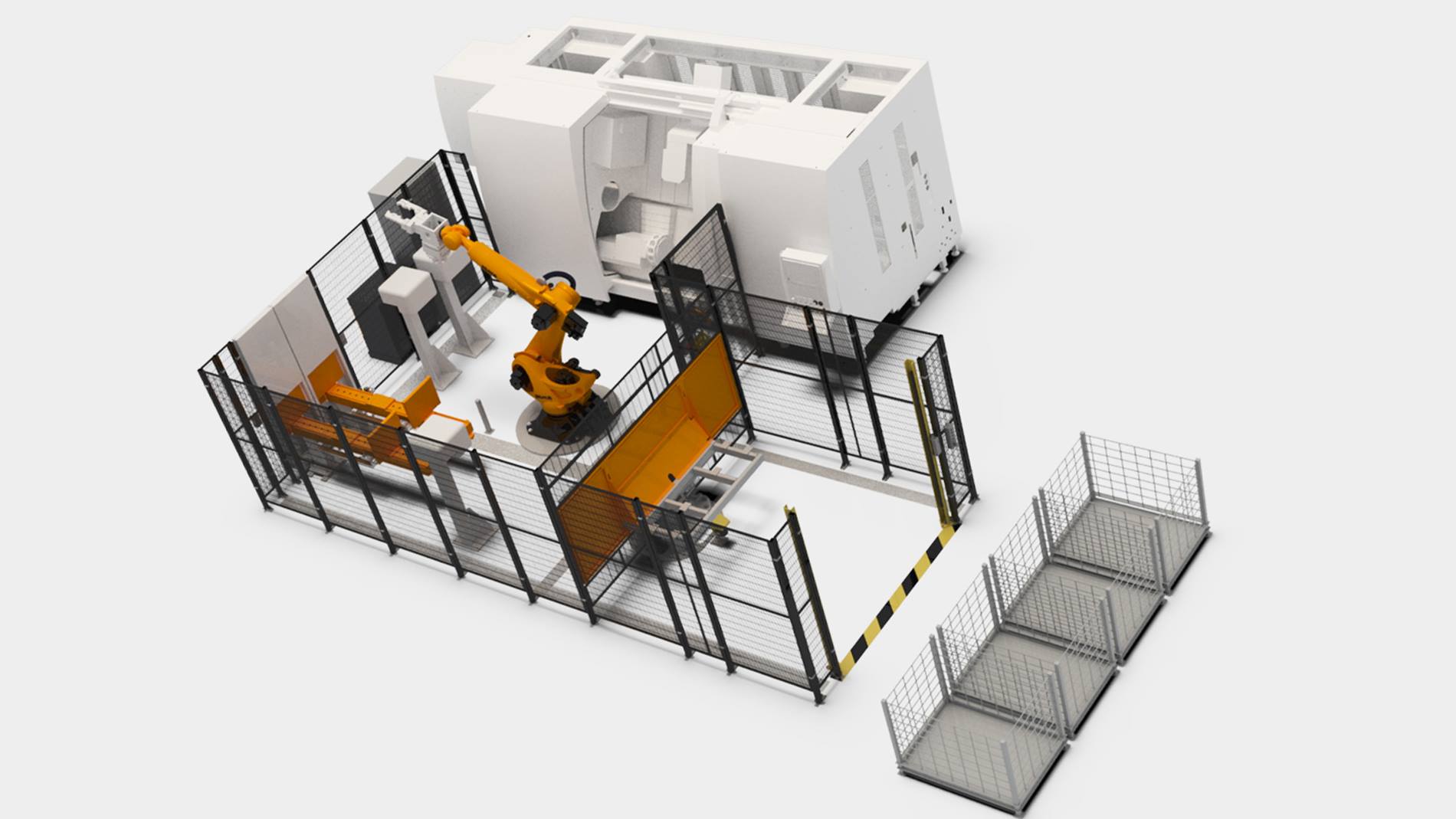

Factors That Can Make Or Break Robotic Cell Design. A robotic work cell is a complete system composed of one or more robots and a controller. This must be considered even at the early stages of the design of the work.

Operational characteristics and specifications. 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. Robot cell design Robot work cell can be organised in to various arrangements or layouts.

These layouts are classified in to 3 basic types Robot. Seamlessly integrate a range of actuators with your robot cell and program directly from the UR pendant without writing a single line of code. Minimize motion Avoid unnatural postures and movements Avoid sharp turns in motion Make moves easy to perform without much concentration Use hands and forearms instead of upper arms and shoulders.

These machines work like ants in an anthill or like bees in a hive. 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. There are many avenues in which an end-user begins to contemplate integrating a robotic cell into his or her facility.

What is a robotic work cell. It may be an organic conception from a project manager something that was. The four cell layout design steps are.

Equipped with a teach mode and manual jogger MachineLogic for Universal Robots. An optimal robotic cell solution are summarized. By Nicholas Trick Motoman Inc.

Vi Control of the work cell The activities of the robot must be coordinated with those of the other equipment in the work cell. CHAPTER ELEVEN ROBOT CELL DESIGN AND CONTROL Industrial robots generaliy work with other pieces of equipment. The operational stock of industrial robots hit a new record of about 3 million units worldwide increasing 13 on average each year 2015-2020.

MachineLogic for Universal Robots enables the control of a variety of motion components directly from a UR teach pendant. INDUSTRIAL ROBOT TECHNOLOGY Unit content 1 Understand the operating design and control principles of modern industrial robots and robot work cells Principles of operation. Not only that but.

Most collaborative robot applications start off as a manual operation. Vii Safety Human protection measures such as fences barriers safety interrupt system with sensors in and around the work cell must be provided. In these cases a fleet of simple insect robots all under the control of one central computer can be used.

A robotic work cell is a complete system composed of one or more robots and a controller. You should begin by analyzing how human workers are currently performing the task. Work Cell Design and Control.

Better lead times more efficient and manpower usage greater volume and product mix greater tolerance requirements and safety improvements are all critical in specifying a robotic work cell. Basically this involves difficult issues like choosing suitable robots and placing them. This article presents a new approach in determining machine layout in robotic cells and the corresponding feasible robot configuration at each machine worksite such that the total cycle.

Analyze and define the manual task map. They install in minimal time and offer the advantage of proven success. View Notes - Lecture Robot Cell Design and Control from ISE 324 at University of Ottawa.

Challenges in robotic cell layout design and optimization Proper configuration for task While designing a robotic cell selecting the most suit-able robot for a given industrial operation is one of the most difficult assignments because of a wide range of physical forms such as cylindrical SCARA articu-. SM is faciliated through use of advanced sensor-based data analytics modelling and simulation in. Tooling Design involves the selection modification and placement of tools.

A robot cell is a complete system that includes the robot controller and other peripherals such as a part positioner and safety environment. 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. Smart manufacturing is integrating networked-based data and information that comprises the real-time understanding reasoning planning and management of all aspects of a manufacturing and supply chain enterprise.

A work cell may also include other equipment depending on the purpose and production method of the cell. Here RC stands for the robot cell. Work cells are an excellent way to improve speed and efficiency in your production line.

54There are 3 types of work part transport system used in in-line robot work cell. The International Federation of Robotics IFR analyzes the Top 5 trends shaping robotics and automation around. The layout of your robotic cell is crucial to its success.

Chapter 5 Contents Robot Cell Layouts Multiple Robots and Machine Interface Some Consideration in Work Cell Design Interlocks Error Detection and Recovery Robot Cycle Time Analysis Introduction Step of a company to implement a robotics program in its operation. The idea here is to use your manual task as a starting point for the robotic cell.

Kuka Cell4 Loading Robot Cell For Efficient Loading And Unloading Kuka Ag

Robot Cell Design Robotic Automation Robot Robotic Welding

Kuka Cell4 Loading Robot Cell For Efficient Loading And Unloading Kuka Ag

Abb S 3dqi Robot Cell Accelerates Quality Control Testing Robot Welding Projects Robotic Automation

Homeostasis And Soft Robotics In The Design Of Feeling Machines Designnewsletter Designnewspaper News Viraldevi Pinned From Feelings Robot Design Robot

0 komentar

Posting Komentar